Power Monitoring Expert – PME

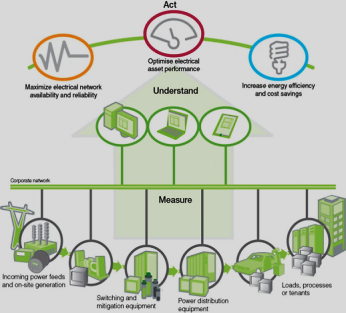

The energy monitoring and management software PME (Power Monitoring Expert) is the base to implement a system for permanent supervision of the electrical network.

In a similar way as happens in major part of the processes, also the electrical network of a facility needs to be monitored and/or managed.

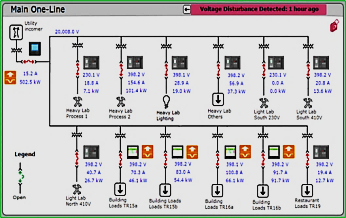

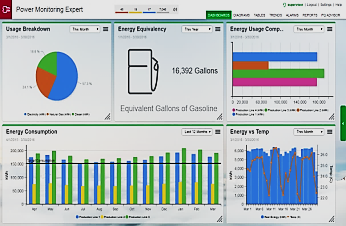

Starting from the data that is collected via communication through the monitoring devices, the software PME provides a large set of tools for real time visualization, storage in SQL database, analysis, processing and calculation of key performance indicators, as well for showing and publishing the useful information that is generated by the system, through customized reports and dashboards, according the particular requirements of each application.

The software PME is indicated for use in every installation where energy is critical as are the sectors of energy generation and distribution, industry in general, large residential, commercial or institutional buildings, data centers, telecommunications, healthcare, etc.

A single monitoring system allows you to centralize the information concerning the operation conditions of the complete electrical network, and not only, of one or several locations.

The access to the data and information that is generated by the system can be done from any place, via web.

The system can automatically send messages, for example, alerting the facilities manager that a disturbance or other anomaly has been detected.

Base on the collected data and respective processing, the system will provide, for the users, the essential information that they need to:

- Improve operational and energetic efficiency

- Reduce the total energy related costs

- Increase the reliability of electrical network

- Reduce line shutdowns and optimize equipment usage rates

- Minimize waste of defective products due power quality problems

- Optimize maintenance planning and life cycle of equipment

- Analyze investments in new equipment

- Support for certification according standard ISO50001

Reduce the total energy cost and improve energy efficiency

Conveniently allocate the energy costs, by each user:

- Cost calculation and reporting by site, process, production line, production shift or equipment

- Implementation of best practices and initiatives for improving energy efficiency

- Monitoring other costs that not only electrical energy – water, steam, gas, fuel, compressed air, etc.

Monitor the energy efficiency, identify opportunities, measure results:

- Measure and compare KPI's between sites, departments processes, etc. and identify possible improvements

- Calculate and confirm the ROI, referring to implemented improvements

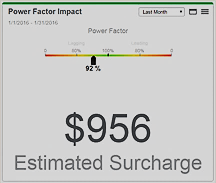

Reduce costs with energy demand, energy usage, reactive energy ...

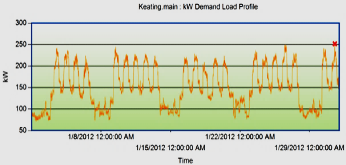

- Alert for the risk of peak demand violation / possibility of selective load shedding

- Possibility of adapting the production plan in order to minimize the energy costs

- Identification of points in the network where the power factor needs to be improved / monitoring of capacitor banks

Reduce costs with energy purchase / improve buying conditions:

- Energy invoice validation; simulation of energy cost in different scenarios

- Negotiation of buying conditions and checking the accomplishment of contractual terms

- Load aggregation

- Evaluation of possibilities for producing your own energy

Improve the usage of installed equipment and plan new investments

Monitoring, as a way to reduce the maintenance costs and increase the useful life of installed equipment:

- Equipment condition evaluation, based on historical trends and real time data

- In addition to electrical, include the monitoring of other parameters – mechanical, environmental or other

Evaluate performance, based on energy consumption:

- Analyze the load profile and demand, for planning the electrical network

- Monitor the losses on transformers UPS, due to nonlinear loads

- Calculate equipment derating, resulting from load unbalance or harmonic distortion

Monitor Power Quality for identifying the problems, the conditions when they occur and ways to prevent them

Validation of compliance with international standards:

- EN50160

- IEC 61000-4-30

- IEEE 519

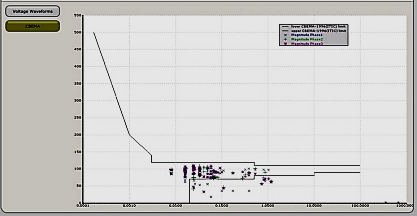

- CBEMA/ITIC

Accurate verification of the power quality compliance in the installation as well the conditions agreed with the energy provider:

- Monitor the power quality in permanence and not only through sporadic audits

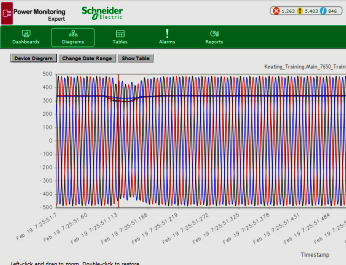

- Monitor sags, swells, interruptions, transients, flicker

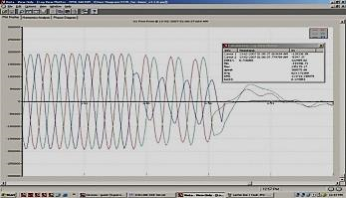

- Fault detection and waveform capture around the instant of the disturbance occurrence

- Prevention of power quality problems, based on historical data

- Sequence of events and root cause analysis

- Identify the origin of the disturbances and the propagation direction

- Diagnostic the causes of occurred faults and unpredicted shutdowns

- Identify the need to install additional power quality mitigating equipment and evaluate the effectiveness of already installed equipment

For additional information, please contact us:

| Av. D. Manuel II 2070 (Ed Plaza) 3º Sala 31 | |

| 4470-334 Maia Portugal | |

| GPS: 41.233311,-8.621470 | |

| Tel: +351 229441992 Call to the national fixed network | |

| Fax: +351 229442079 | |

| geral@emr.pt |